TECHNOLOGY

UP TO A TENFOLD INCREASE

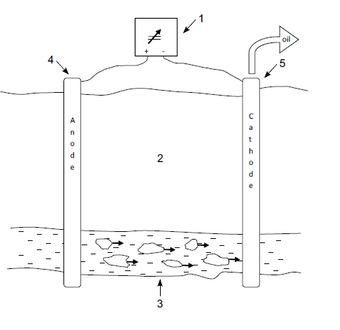

The EOR technology is an electrochemical based method for electrically enhanced oil recovery by inducing a low electric DC current into the formation.

On landbased operations we use the existing well casing as electrode. The setup consists of two electrodes, where one is an anode and the other a cathode.

The process breaks down the long chained molecules, which means that the heavy oil is being transformed into lighter fractions. This stage of the process is called liquefaction. Full scale test have shown that oil with an API gravity of 15 over a period of 45 days is changed into an API gravity of 39 to 40.

The second stage of the process creates a flow of oil and water towards the cathode. Full scale tests have shown up to a tenfold increase in the oil production.

The EOR technology is used in normal producing oilfields as well as in "exhausted" oilfields.

REFINING THE OIL

By applying our patented EOR technology, the heavy oil is chemically converted into lighter oil, which is not reversible (as opposed to using heat as a method for liquifying the oil).

The largest problem for the global oil and gas industry is the low extraction rates from current oil reservoirs. Today on average only 30-35% of the oil reserves can be extracted using current technologies, leaving approximately 65-70% still in the reservoir. A significant reason is that the remaining 65-70% of the oil is too thick to allow itself (or be forced) to flow in the reservoir formation towards the pumping well.

Using the patented EOR technology, the heavy oil is chemically converted into lighter oil, and unlike when using heat for liquefaction this becomes a permanent state.

EORTEC is the only enhanced oil recovery-based company in the world capable of making heavy crude oil permanently more fluent by changing the chemical composition of the oil.

CONTACT US

EORTEC

EORTEC has more than 20 years of experience in using electrochemistry processes. The technology has been testet in North America and Denmark, and implemented in oilfields situated in Indonesia, Albania and Austria.

© Copyright EORTEC 2017. All Rights Reserved.